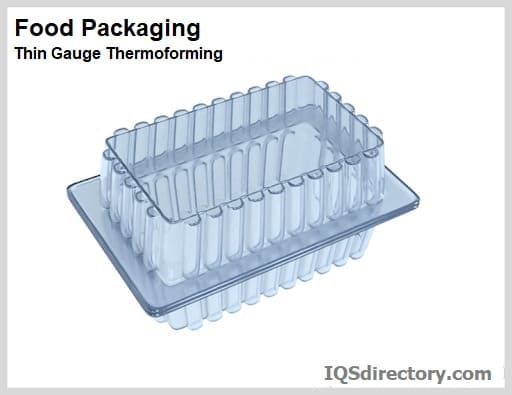

High-precision thermoformed packaging designed to protect, preserve, and present your products with exceptional clarity and durability. Ideal for food, medical, electronics, and consumer goods.

| Specification | Details |

|---|---|

| Material Options | PET, PVC, PP, PS, APET, RPET, HIPS, PLA (biodegradable) |

| Thickness Range | 0.1mm to 3.0mm (customizable based on application) |

| Forming Technology | Vacuum forming, pressure forming, twin sheet forming |

| Maximum Forming Size | Up to 1200mm x 800mm (custom sizes available) |

| Tolerances | ±0.2mm standard (±0.1mm for precision applications) |

| Surface Finishes | Glossy, matte, textured, anti-fog, anti-static |

| Special Features | Peelable lids, tamper evidence, embossing, printing |

| Certifications | FDA, EU 10/2011, ISO 13485, RoHS compliant |

| Production Capacity | Prototypes to high-volume production runs |

We help you select the optimal plastic material (PET, PVC, PP, etc.) based on your product requirements, considering factors like clarity, rigidity, and food safety compliance.

Plastic sheets are precisely heated to their forming temperature in our computer-controlled ovens, ensuring consistent material properties throughout the sheet.

The heated plastic is formed over molds using vacuum, pressure, or mechanical assistance to create precise, repeatable shapes tailored to your product.

Excess material is precisely trimmed using CNC routers or die-cutting to create clean edges and exact dimensions for your packaging.

Each piece undergoes rigorous quality checks for dimensional accuracy, wall thickness consistency, and visual defects before packaging.

Finished products are carefully packaged to prevent damage during transit, with options for bulk packaging or retail-ready presentation.

High-quality packaging solutions for various industries

Clear, durable packaging ideal for retail products. Available in PET, PVC, and RPET materials.

Secure packaging for pharmaceuticals, electronics, and small consumer goods. Customizable cavity sizes.

Leak-proof containers for fresh produce, meats, and ready meals. Compatible with MAP technology.

Sterile packaging solutions for medical devices and instruments. Custom-formed to your specifications.

Precision-formed trays for sensitive electronic components. Available in conductive and anti-static materials.

Eco-friendly packaging made from recycled or biodegradable materials. Custom solutions for green initiatives.

Our state-of-the-art thermoforming equipment and CAD/CAM design capabilities ensure precision and consistency in every product we manufacture.

Rigorous quality control processes at every stage of production ensure that our packaging meets the highest industry standards and your exact specifications.

Our engineering team works closely with you to develop custom packaging solutions that perfectly fit your product and meet your marketing objectives.

We offer a range of eco-friendly materials and processes to help reduce your environmental impact without compromising on performance.

From prototype to production, we offer competitive lead times to help you get your products to market faster.

Our efficient manufacturing processes and bulk material purchasing allow us to offer competitive pricing without sacrificing quality.

Our packaging experts are ready to help you find the perfect solution for your products.